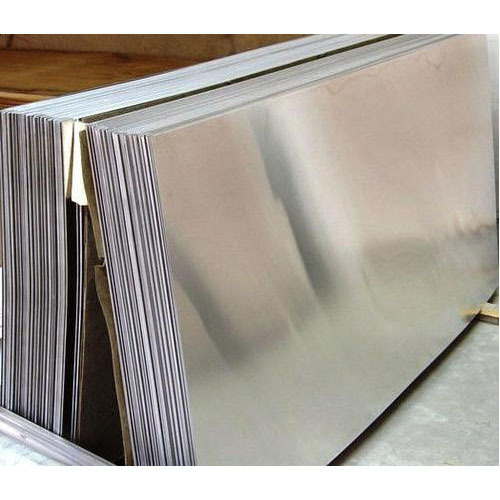

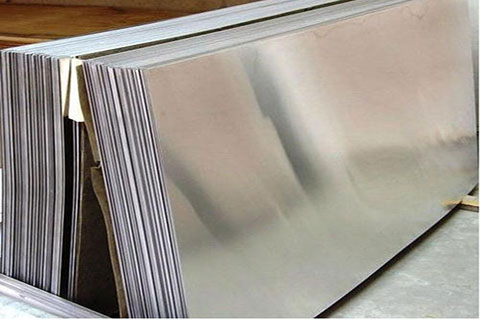

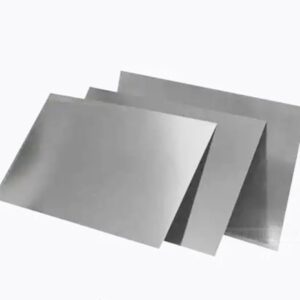

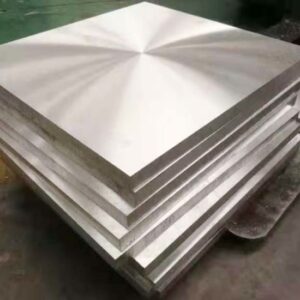

Magnesium Alloy Plate/Sheet

• Process: Semi-Casting & Hot Rolling, Hot Rolling.

• Size: Max thickness 300mm,Width 3000mm, Length 6000mm

• Surface Treatment: Water Polishing & Machining, Perfect Clean & Bright & Flatness.

• Inspection of inner quality: By imported ultrasonic flaw detection inspection equipment UI-25.

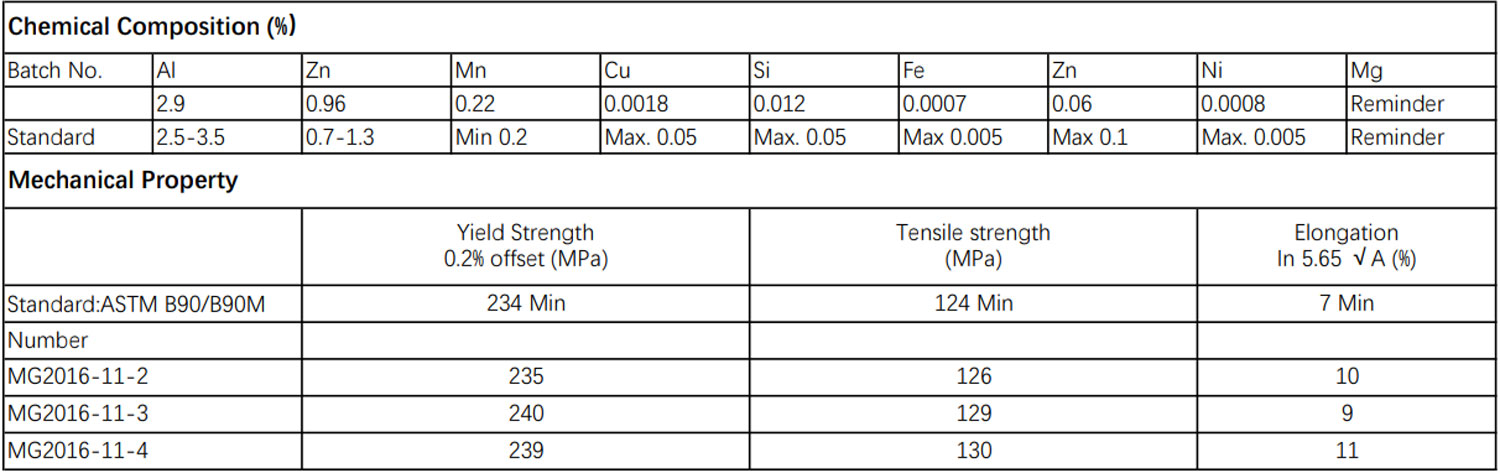

• Material AZ31B H24; H26;AZ91D;AZ80A

• Technology Inspection & Produce Standard

ASTM B90/B90M-07; AMS 4375; AMS 4376; AMS 4377

Also can produce as clients’s stardand.

Detailed Information

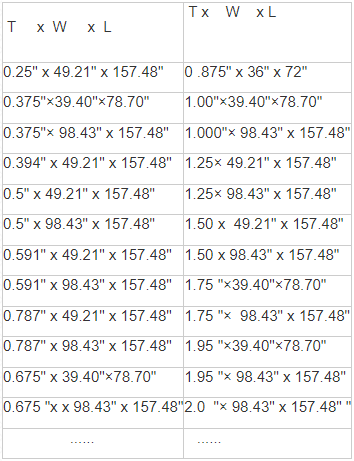

MaximumThickness: 0.5-6mm

Maximum width: 2000mm

Maximum length: 6000mm

Also production as clients’ requirement sizes .

• Physical Properties

Density: 1.78g/cm3;

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa;

Poissons ratio: 0.35;

Melting range: 566 – 632°C

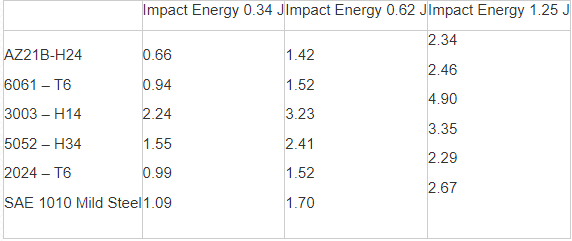

• Dent Resistance

Weight for weight, AZ31B-H24 has proven to be superior to competitive materials in its resistance to denting at moderate energy levels.

Dent Resistance of 1mm Gauge Sheet (Dent depth in mm from 25mm spherical redius indentor on 350mm span)

• Heat Treatment: No thermal treatment is available for increasing the strength of this alloy after fabrication.

• Inspection: Using import Ultrasonic flaw detector and ICP equipment from Japan equipment , Before rolling , make testing and slag detection process, ensuring the slab and plate interior without defect and chemical composotion .

1.Magnesium alloy sheet is an indispensable material in the aviation and aerospace industries. The aluminum material used in the aircraft now accounts for about 85% of the total weight of the aircraft. The high-strength, corrosion-resistant magnesium alloy plate has better performance than the aluminum plate, and has more advantages in the application of the aircraft.

2.Magnesium alloy is an ideal structural material to reduce the quality of weapons and equipment, realize the lightweight of weapons and equipment, and improve the tactical performance of weapons and equipment.

3.Applications in vehicles, such as automobiles, trains, ships, etc., to reduce weight, save energy, and reduce pollution, the country is vigorously developing.

4.Widely used in 3C products.

5. In the application of power supply, magnesium power products are high-energy and pollution-free power supplies, such as the manufacture of magnesium-manganese dry batteries, magnesium air batteries, magnesium seawater batteries, torpedo power supplies and power batteries.

6.High-potential magnesium alloy sacrificial anode plate is used for metal protection.

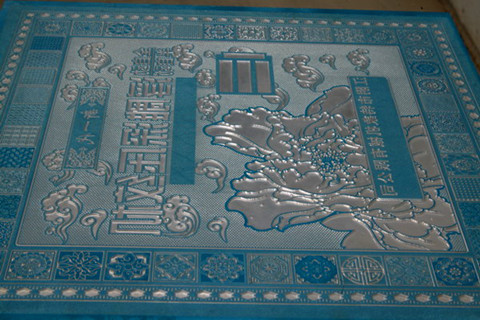

7.Civil use is also very wide. Such as environmental protection building decorative plates, sports, medical equipment, tools, advanced spectacle frames, watch cases, 8. Premium travel goods, etc.

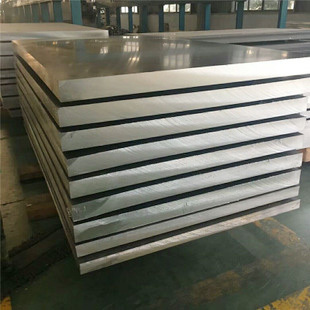

Packing : Export packing standard , seaworthy packing , plastic film packed and put into strap bundled plywood case .

Reviews

There are no reviews yet.