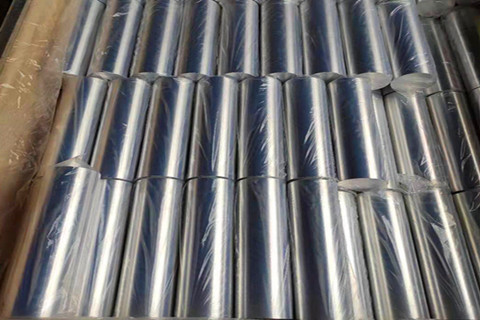

Magnesium Etching Plate/Sheet

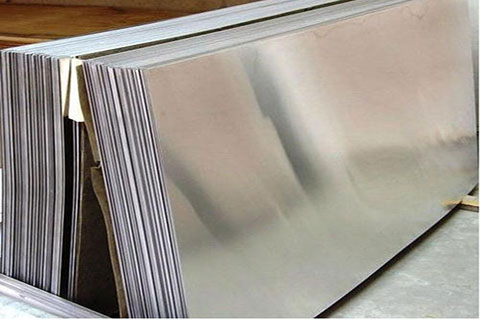

• Process: Semi-Casting & Hot Rolling, Hot Rolling.

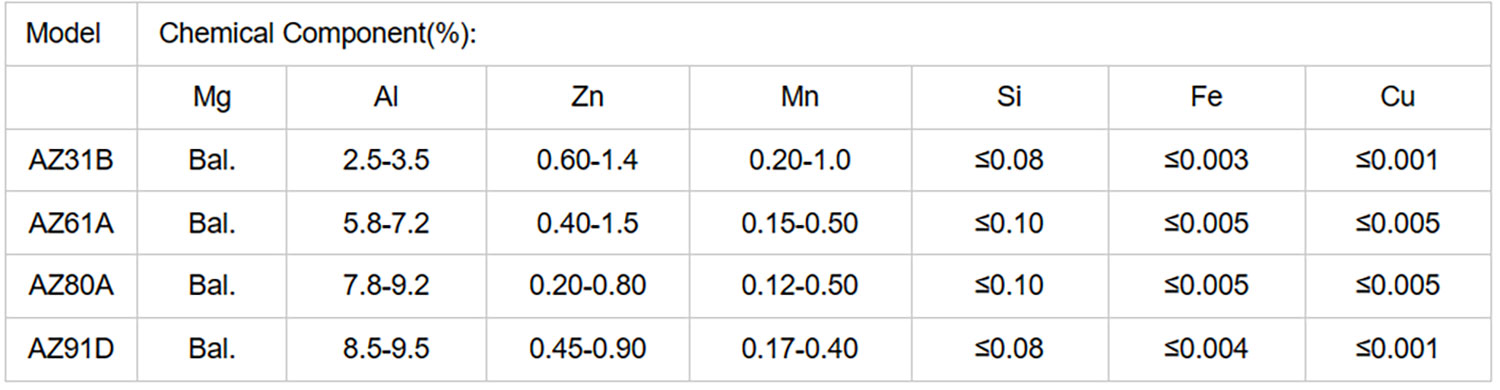

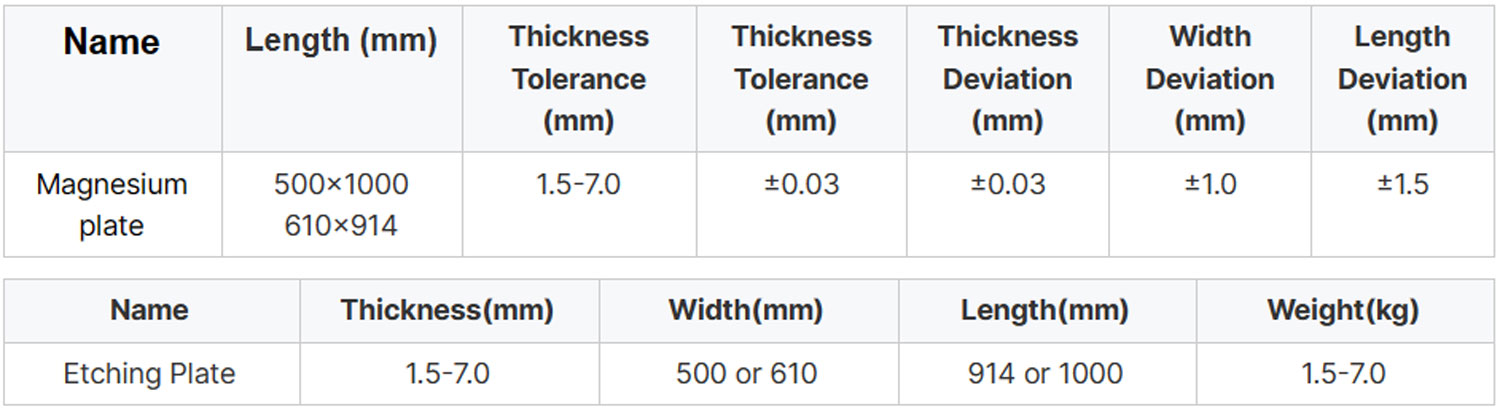

• Size: 1mm – 7mm thickness, Width 610mm, Length 914mm or can customized.

• Surface Treatment: Water Polishing & Machining, Perfect Clean & Bright & Flatness.

• Inspection of inner quality: By imported ultrasonic flaw detection inspection equipment UI-25.

Characteristics:

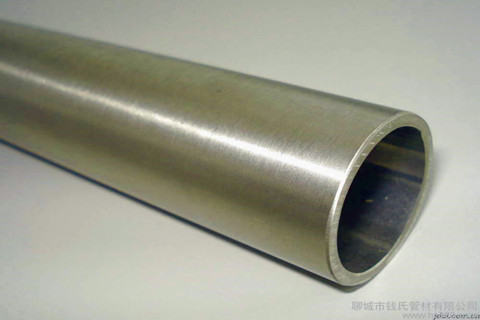

1. Magnesium plate is with light weight, thermal conductivity, heat transfer and heat dissipation, high surface hardness, stripping easy.

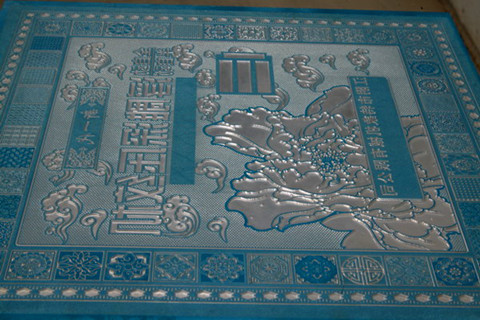

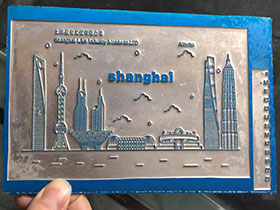

2. Magnesium plate as corrosion of metallic material has many advantages, making etched magnesium plate in the world , is widely used in printing, packaging, plate , decoration and so on in the field.

3. In the paper packaging industry, etched magnesium plate is used as a gold foil version and embossing plate . Same size templates, relatively light weight magnesium board, transportation, installation , sticky boards are convenient. Heat capacity than the etched magnesium plates , good bronzing effect, bright gold , patterned fine and shiny.

4. In particular, the magnesium plate stamping faster than copper , zinc plate number, resistance rate 20% higher than copper , and can effectively improve the processing speed , saving labor costs.

2. Developing: Use NaOH solution, suggested solution temperature is 21-29℃.

3. Touch up: Examine the developed plate for flaws and touch up as needed.

4. Descumming: Put finished plate into 3%-5% (Volume) nitric acid solution, use brush to clean the plate surface. Apply

Arabic gum evenly on the plate surface after cleaning with water, and then the plate is ready for next step etching.

5. Etching bath preparation: Prepare it for different etching plate accordingly.

6. Etching settings: Set the etching data for different plates.

7. Bath acid replenishment.

8. Top coating removal (optional).

Magnesium plate is with light weight, thermal conductivity, heat transfer and heat dissipation, high surface hardness, stripping easy. Magnesium plate as corrosion of metallic material has many advantages, making etched magnesium plate in the world , is widely used in printing, packaging, plate , decoration and so on in the field.

Reviews

There are no reviews yet.